Aplin & Barrett's western Counties Creameries Ltd

aplin & barrett

Western Counties Creamery Ltd., Newton Road

In

1888,

James Shorland

Aplin and

William Henry

Barrett merged

their wholesale

dairy businesses

together for the purpose of creating and marketing cheese, cream and butter.

In

1888,

James Shorland

Aplin and

William Henry

Barrett merged

their wholesale

dairy businesses

together for the purpose of creating and marketing cheese, cream and butter.

In 1891 the Western Counties Creamery moved to Marston Magna from Rimpton and in 1898 it was amalgamated with Aplin and Barrett Ltd.

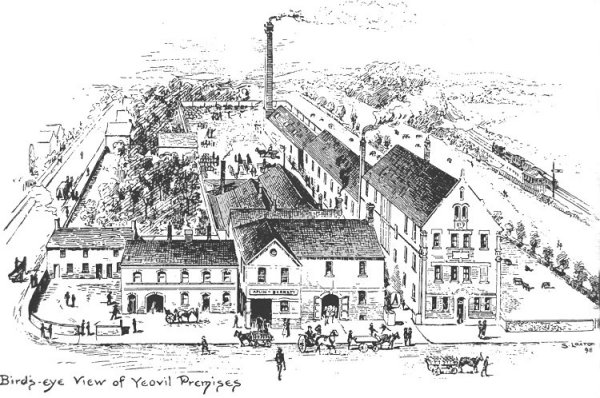

Around the turn of the century Aplin & Barrett acquired some two acres of land on the eastern side of Newton Road, near its junction with Middle Street, that had been the extensive grounds of Osborne House. The decision to purchase was undoubtedly enticed by the close proximity of Yeovil Town Railway Station and its associated goods yard at the heart of a potential national distribution system for their products.

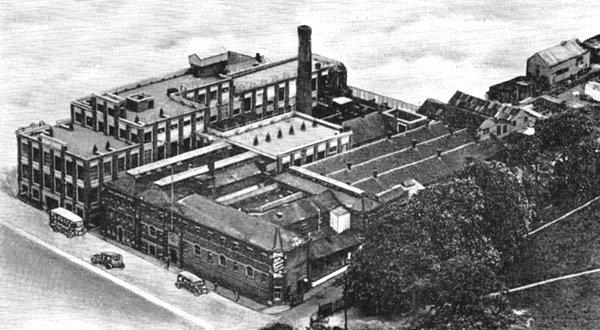

The aerial perspective sketch above, of 1898, shows the planned factory and office buildings which were constructed by the time of the 1901 Ordnance Survey. At left is Lower Middle Street and Newton Road runs across the bottom of the drawing. At extreme left were three existing houses occupied in 1891 by the families of a brewer's cellarman (clearly of the Osborne Brewery that the proposed site backed onto), a mason and a leather dresser. Featuring prominently in the sketch, at right, is the railway that prompted the positioning of the factory. The corner plot at the junction of Newton Road and Middle Street was, of course, to become the site of the Western Gazette offices but in 1901 their offices were on the opposite corner of Newton Road. It is clear, by comparing the sketch above with the Ordnance Survey map of 1901 below, that the factory was built pretty much as the sketch. However the two blocks of buildings on the very corner, one looking like three cottages and the other appearing like a small factory building and shaded blue on the map below, were already existing while Aplin & Barrett contemplated their new factory because they appear on the 1886 Ordnance Survey. Whether or not these buildings were incorporated into the new factory, as suggested by the aerial sketch above, is not known. However they did not survive the decade since the Western Gazette offices were built at this location in 1906.

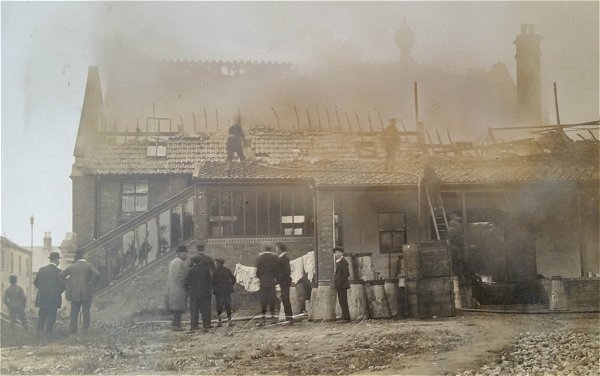

By comparing the sketch above with the photograph of the 1912 fire below, it will be seen that the right-hand building in the sketch is the building at left in the photograph. This means that the field to the right of the building in the sketch had the building on the right in the photograph built on it by 1912.

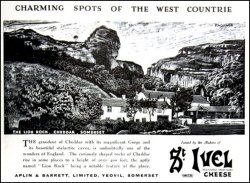

|

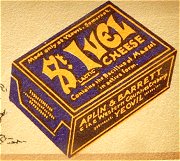

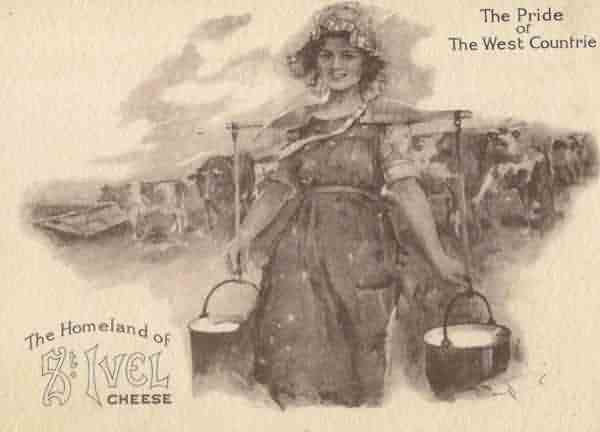

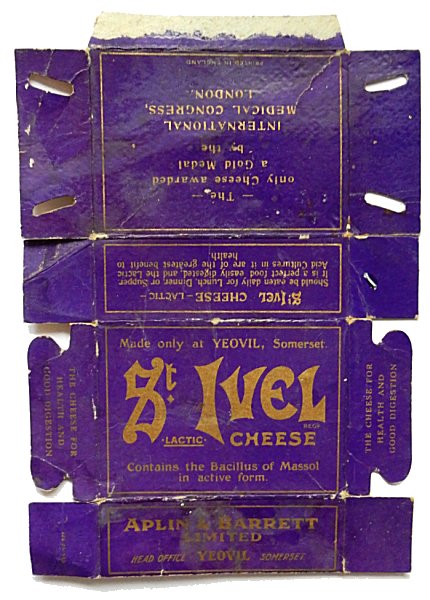

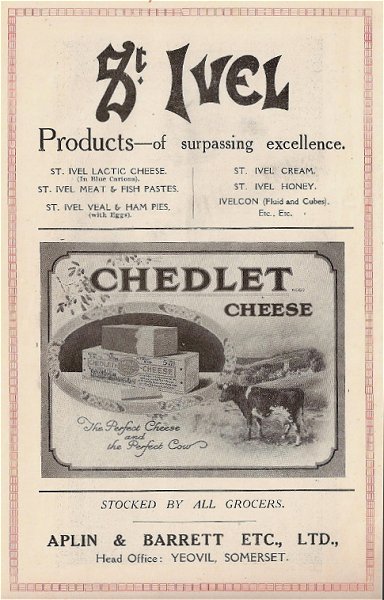

The St Ivel brand was born in 1901 and applied to a range of their products, even though there is no saint of that name. In fact Ivel was one of the spellings accorded to Yeovil by John Leland in his Itineraries of 1533-46. Nevertheless the brand became well established, nationally famous and included butters, creams and cheeses. Their famous 'St Ivel Lactic Cheese' was introduced in 1909. |

|

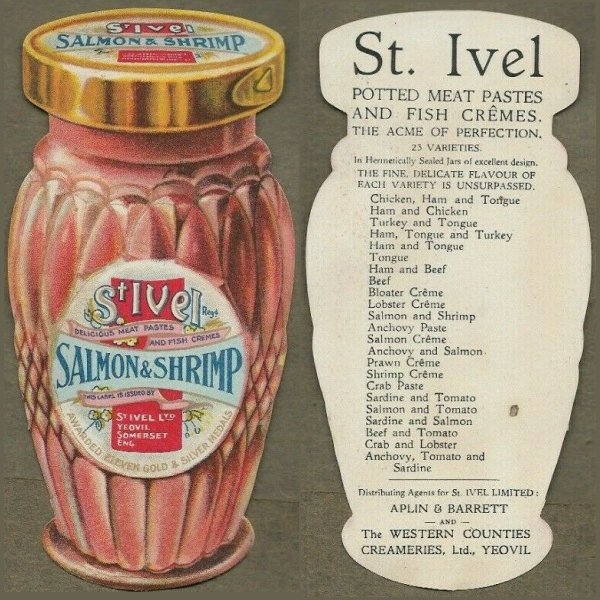

EED Marden’s cheese and milk company was absorbed into the Western Counties Creameries and, by similarly incorporating WT Maynard’s meat processing company, Aplin & Barrett also produced a limited range of meat products such as pork pies, sausages and potted pastes.

On 11 August 1912 a fire took hold in the factory but fortunately was contained within one wing containing most of the office accommodation and part of the creamery. The fire was watched by a crowd of several hundred but eventually put out by the fire brigade with assistance from the Sherborne fire brigade and, apparently, two members of the London fire brigade who happened to be visiting Yeovil at the time. The Western Gazette reported “new and valuable machinery and a very large stock of a most inflammable character” were contained in the buildings.

Photograph of the disastrous fire of 11 August 1912.

The final estimate for the damage caused amounted to between £15,000 and £20,000 (between £1.5 million and £2 million at today's value). In the photograph of the fire, above, it will be seen that the building at left is identical to the building at right in the early aerial sketch, while the burning building at right in the photograph was clearly a later building constructed in the field at extreme right of the sketch.

From my

collection

The fire blazes and consumes the roof, before the fire brigade could get it under control.

Courtesy of Bill and Audrey Robertson

The fire brigade in attendance - at high level two fire fighters hose down the smouldering building.

Another photograph, this reproduced as a postcard, is by Witcomb & Son.

The side of the building showing the damage after the fire. Another Witcomb & Son postcard.

From my

collection

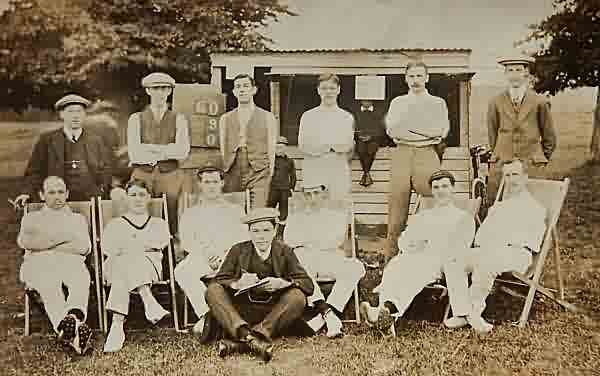

The St Ivel Cricket Club, 1913.

Courtesy of

Peter Guppy

Visitors to the Aplin & Barrett factory inspect the finished product. The two men in dark pinstripe suites were British comedy film stars Graham Moffat (left) and Moore Marriott (right) who were in Yeovil in March 1938 to promote the film "Oh! Mr Porter” at the Gaumont Palace.

Courtesy of

Peter Guppy

Screen comedians Graham Moffat and Moore Marriott in mock fight over the free samples. At right wearing the hat is Edward Guppy (1873-1954) who rose to become the Company Secretary of Aplin & Barrett.

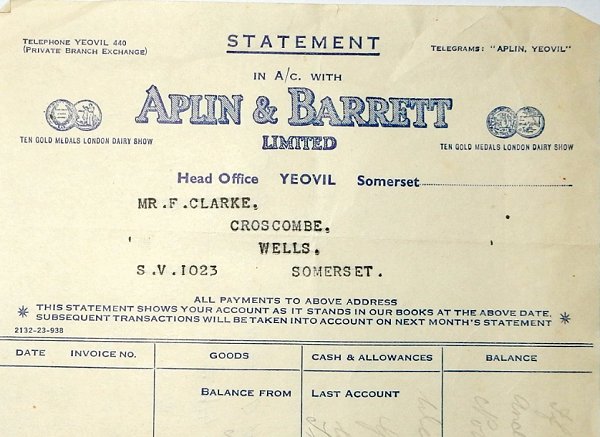

An Aplin & Barrett's letterhead from 1940. Notice that they were contracted to the War Office and the Admiralty to help the war effort.

Courtesy of

Maxine Hawker

(colourised)

More girls of Aplin & Barrett's staff pose for a photograph in the late 1940s. Only two ladies are known - Elsie Barry (front row, 8th from left) and Constance Beaumont (the short lady in the middle of the second row from the front, wearing glasses). Can you name any of them others

This

colourised photograph

features in my

book 'Yeovil From Old Photographs'.

A photograph of around 1982 showing the St Ivel sign on the southern end of the factory - a familiar sight to many Yeovilians. Note the decorative 'AB' monograms on the corner piers.

The modernist new building of 1932. Empty and awaiting conversion in 2013.

The present building, a modernist edifice in concrete and brick, was built in 1931 and 1932 as witnessed by these dates incorporated into the various rainwater hoppers around the building and shown in the detail photograph in the gallery below.

From my

collection

An artist's impression of the Aplin & Barrett factory in the 1950 Yeovil Guide.

In 1957 Aplin & Barrett produced the first commercial extract of nisin, an antibacterial peptide used during the manufacture of processed cheese, meats, beverages and so forth in order to extend the products’ shelf life. In 1960 the company was acquired by the Unigate Group who closed the Yeovil premises in 1976, transferring many of their staff to other branches, particularly Westbury, Wiltshire. The St Ivel brand, however, continued long after the closure of Aplin & Barrett. Aplin & Barrett's corporate, accounting and employee records from 1898 to 1961 are held in the Wiltshire & Swindon Records Office.

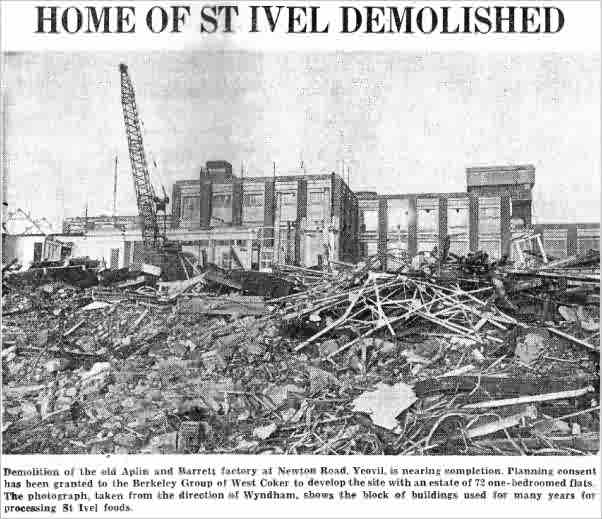

Much of the building was demolished in January 1983, prior to the building of Ivel Court.

MAP

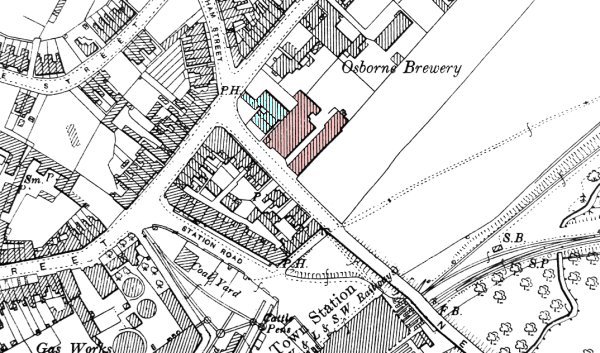

Map based on the 1901 Ordnance Survey. Aplin & Barrett works shown pink. Buildings shaded blue were possibly incorporated into the factory complex but had been sold to the Western Gazette by 1905.

GALLERY

From my

collection

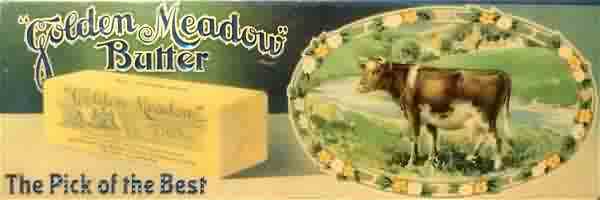

Both sides of a cardboard cut-out advertising bookmark for Aplin & Barrett's "Golden Meadow Butter" from around 1895.

An advertisement of around 1900 for Aplin & Barrett's 'Golden Meadow' butter.

Courtesy of

Roger

McElliott

A later advertisement for Golden Meadow butter.

Courtesy of

Roger

McElliott

.... and another.

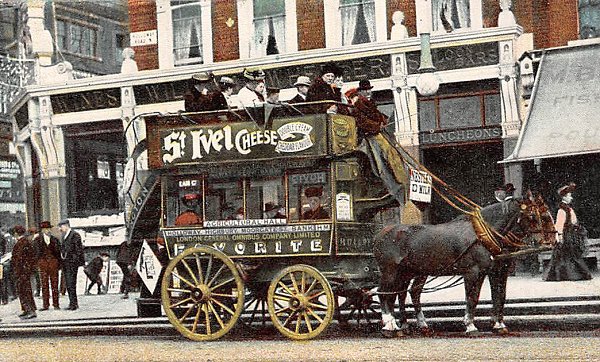

A postcard from around 1900 advertising St Ivel cheese on the side of a London omnibus.

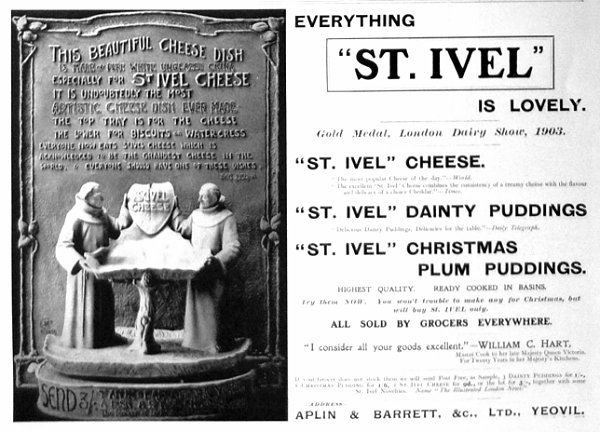

An early 'St Ivel' advertisement from a 1903 edition of the London Illustrated News. The St Ivel cheese dish is described as "This beautiful cheese dish is made of fine white unglazed china especially for St Ivel cheese. It is undoubtedly the most artistic cheese dish ever made. The top tray is for the cheese the lower for biscuits and watercress."

... and here is the actual St Ivel cheese dish.

Courtesy of

Philip

Jenkins

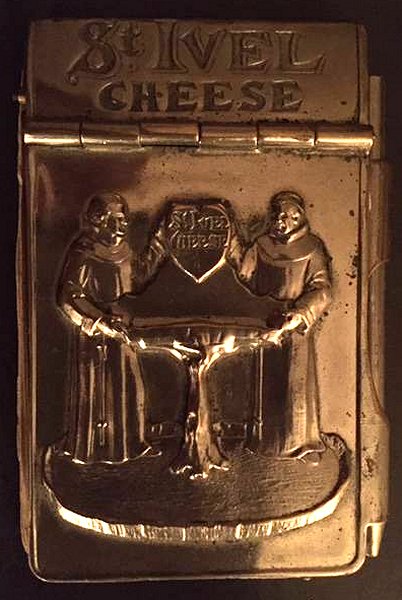

A complimentary note pad (it's actually made of silver) given away by the company.

Courtesy of

Philip

Jenkins

The reverse of the above complimentary silver note pad.

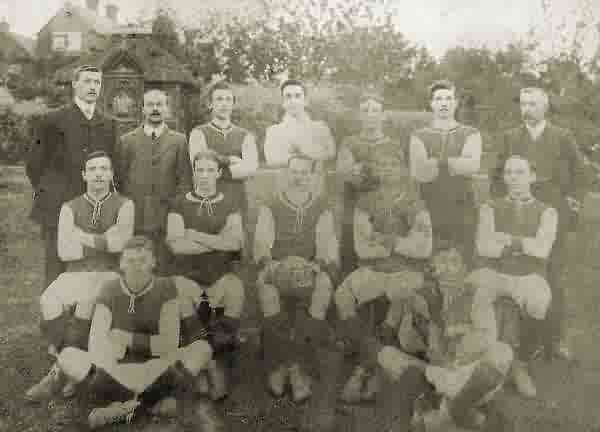

The 1909 'St Ivel' football team.

An Aplin & Barrett advertisement from the inter-war years.

Both sides of a cardboard advertising cut-out for Aplin & Barrett's range of 23 potted meat and fish pastes - probably from the inter-war years.

From my

collection

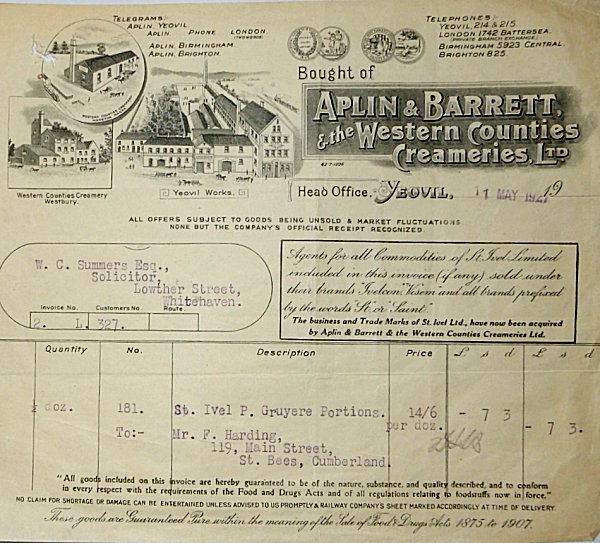

An Aplin & Barrett invoice dated 3 May 1919.

From my

collection

A later Aplin & Barrett letterhead style, probably from the 1950s.

From my

collection

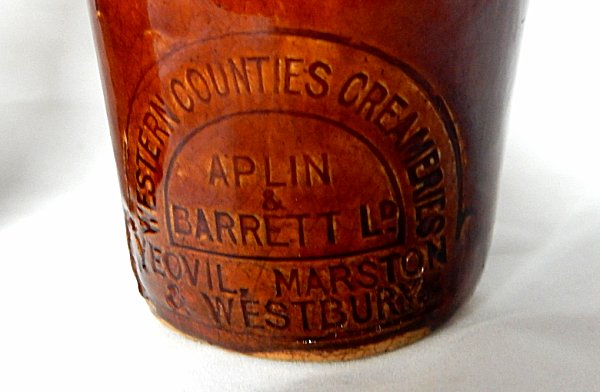

Aplin & Barrett treacle-glazed stoneware cream jugs and pots.

From my

collection

Aplin & Barrett treacle-glazed stoneware cream jugs - each has a pouring lip at the top and a handle. The smaller one is 3" (75mm) high, the larger stands 3¾" (95mm) high.

From my

collection

Aplin & Barrett treacle-glazed stoneware cream pots - with a plain, round top and no handle. The smaller one is 3" (75mm) high, the larger stands 3¾" (95mm) high.

From my

collection

All the Aplin & Barrett treacle-glazed stoneware cream jugs and pots carried this logo.

From my

collection

While the

cream jugs

with handles

shown above

are

relatively

common, this

cylindrical

Aplin &

Barrett

treacle-glazed

stoneware

pot is quite

rare. It

stands 3½

From my

collection

A give-away set of miniature playing cards - made for Boots the Chemists (or in this case Boots the Cash Stationers) and issued by Aplin & Barrett to advertise St Ivel cheese.

From my

collection

A box containing St Ivel Lactic Cheese. The box, when assembled, measures 4" x 2¾" x 1¼" (100mm x 70mm x 32mm).

From my

collection

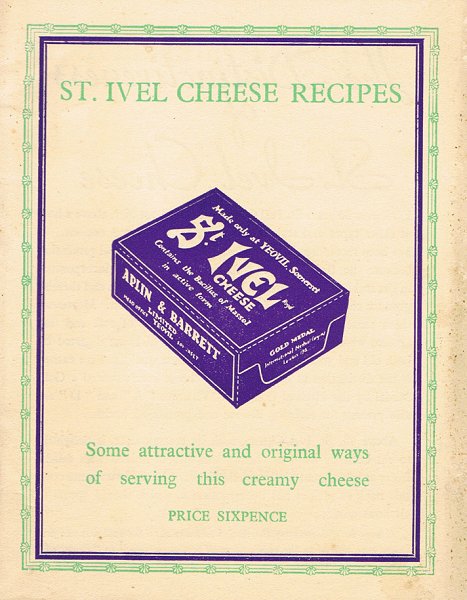

Attractive and original ways of serving St Ivel cheese from the 1920s.

From my

collection

Prices and varieties of sandwich pastes, dated 6 October 1939.

Courtesy of

Julie Crang

One of two Veal & Ham Pie wrappers (from the 1950s ?) found under floorboards during a house renovation - clearly a builder's lunch.

Courtesy of

Viv Cafferkey

The 'paste shop' where pots of fish or meat paste are filled and packed (see article at bottom of page). Photographed (colourised) in the 1940s. The lady at centre is Peggy Andrews née Beaton.

Courtesy of

Andrew

Bridge

An Aplin & Barrett 'St Ivel' glass pot used for fish or meat pastes and shown in the packing process in the previous photograph. This example was found by Andrew in Accrington, Lancashire, while walking through an area that had previously been an old rubbish tip.

![]()

|

|

Above

left

is a

Christmas

advertising

from

around

1910

- a

cardboard

bookmark.

The

prettily

posed

skater

with

the

product

on

her

lap

is

selling

'Ivelcon',

a

beef

extract

beverage

sold

in

cube

form.

The

name

of

the

product

combines

the

name

of

the

brand,

'St

Ivel'

with

the

word

‘consommé’.

The

back

of

the

bookmark

describes

Ivelcon

as

“an

absolutely

pure

Food

Beverage,

containing

the

concentrated

essence

of

Prime

Beef

and

Fresh

Vegetables”.

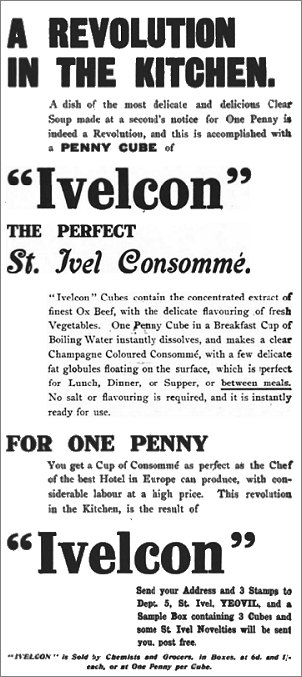

Above

right

is

one

of

the

very

first

advertisements

for

'Ivelcon'

from

the

21

September

1908

issue

of

the

London

Daily

News.

Above

left

is a

Christmas

advertising

from

around

1910

- a

cardboard

bookmark.

The

prettily

posed

skater

with

the

product

on

her

lap

is

selling

'Ivelcon',

a

beef

extract

beverage

sold

in

cube

form.

The

name

of

the

product

combines

the

name

of

the

brand,

'St

Ivel'

with

the

word

‘consommé’.

The

back

of

the

bookmark

describes

Ivelcon

as

“an

absolutely

pure

Food

Beverage,

containing

the

concentrated

essence

of

Prime

Beef

and

Fresh

Vegetables”.

Above

right

is

one

of

the

very

first

advertisements

for

'Ivelcon'

from

the

21

September

1908

issue

of

the

London

Daily

News.

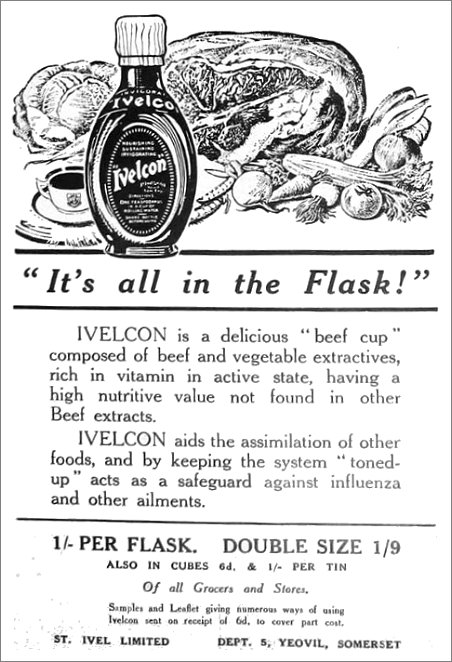

Promoted as healthy, warming and strength-building drinks or tasty cooking supplements, these products were widely advertised. Ivelcon continued to be advertised into the 20th Century. In 1918 an advert in the Illustrated London News promoted the cube’s benefits: “It’s all in the Cube! Drink a cupful of Ivelcon just before going to bed. You will not only find it sufficient as a light meal to carry you over until the morning, but it will bring refreshing sleep”.

Above left is a brown glass 'Ivelcon' bottle from the 1920s, shown slightly larger than lifesize - it measures 4.25" (107mm) tall and 2" (50mm) across. The word 'Ivelcon' is embossed very lightly across the shoulder of the bottle.

Before the Great War, when the product was comparatively new, Aplin & Barrett's advertisers worked a scheme of house-to-house sampling of their Ivelcon beef extract beverage, with demonstrations. The canvasser asked for hot water and prepared a sample cup if Ivelcon beef-tea for the householder in anticipation of a sales order.

From my

collection

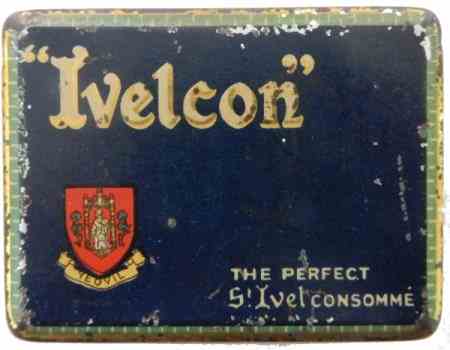

A small tin (2¾" x 2" x ¾" - 65mm x 50mm x 20mm) that held twelve individual portions of 'Ivelcon' beef consommé. This was almost certainly sent to troops serving in the Great War.

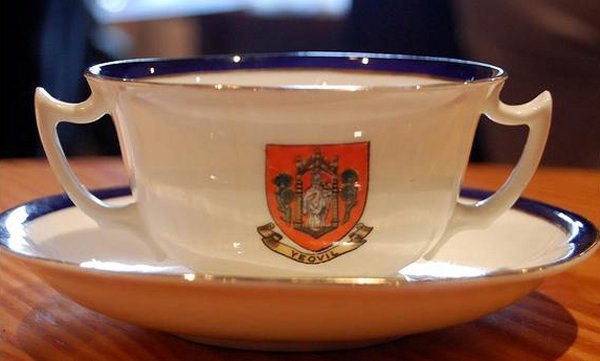

An Ivelcon advertisement from 1918. Note the specially-designed Ivelcon cup (see below). Other advertisements of the time noted "A Perfect 'Beef-Cup' for One Penny. Made in a Moment".

An advertisement in the 6 January 1923 edition of The Graphic for Aplin & Barrett's 'Ivelcon' meat extract

This is a specially designed promotional cup and saucer to promote Aplin & Barrett's 'Ivelcon' meat extract between 1908 and 1925. The cup measures 4.25" across and the saucer is 6" in diameter.

.... and on the bottom of the cup were complete instructions.

Identical to the standard Ivelcon cup in every way, but this special edition was a souvenir of the 1911 coronation of George V.

![]()

From my

collection

In the 1920s Aplin & Barrett published this book of tours of the West Country - each page featured a small advertisement (see below) for one of their products.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

From my collection

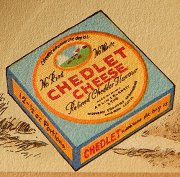

Product advertisements from the pages of the 1930's 'The Call of the West' tour guide, above. All are enlarged from the original size.

![]()

Courtesy of

Linda Dewar

This colourised photograph of the late 1960s, shows the Aplin & Barrett typing pool.

Aplin & Barrett's Newton Road elevation photographed in 1969 before the demolition of the right-hand building.

The front of the now-empty building. |

1954 Advertisement for St Ivel. |

|

|

||

|

The rear partly demolished. | ||

The date cast into the rainwater hopper. | ||

|

|

|

|

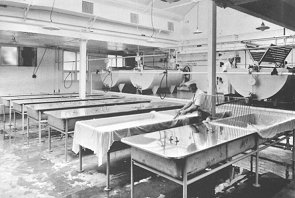

The

cheese-making

room,

circa

1960. |

The Aplin & Barrett sign in concrete. | |

The building from Summerhouse Hill. |

The building from Wyndham Hill. |

An advertisement of 1928 for Aplin & Barrett's 'St Ivel' brand products.

.... and more recently - labels from various flavoured cheese spreads. The St Ivel brand was retained by Unigate after the acquisition of Aplin & Barrett In 1960 and after the closure of the Yeovil premises in 1976.

A colourised photograph of Aplin & Barrett's stand at the Yeovil Show, held at Barwick Park. Photographed during the 1950s.

The Newton Road face of Aplin & Barrett shortly before demolition began in 1983, prior to building Ivel Court.

Demolition prior to building ivel court, 1983

Courtesy of

Rob Baker

A photo and caption from the 21 January 1983 edition of the Western Gazette.

The following photographs are courtesy of Rob Baker and show the demolition of part of the factory prior to the building of Ivel Court on the site.

Courtesy of

Paul Rimmer

Once the site had been cleared, the new block of flats was constructed and seen here in late 1983 or early 1984. Initially called Berkeley Flats, it is now Ivel Court.

the 'ST IVEL' postcards

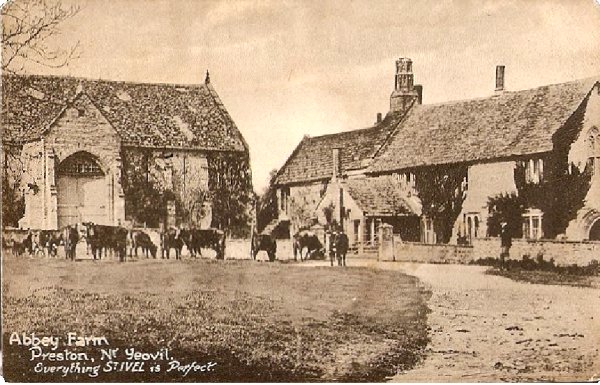

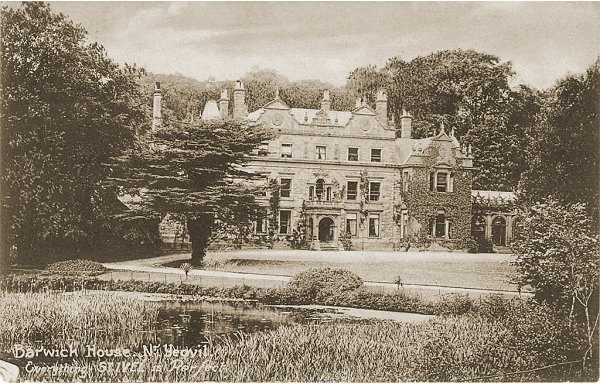

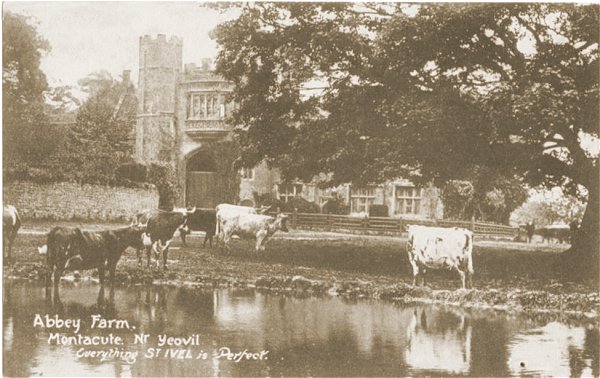

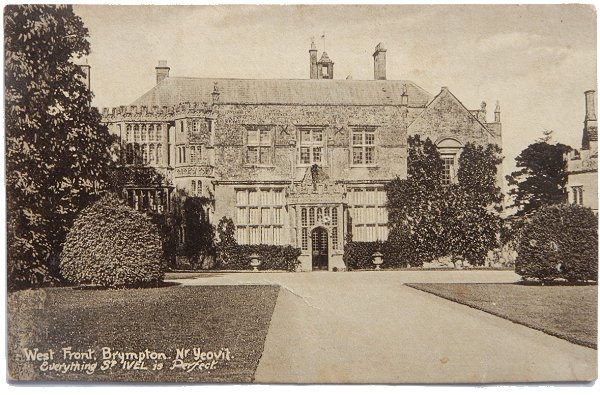

The following was a series of 12 postcards entitled "Series 1 - Beautiful Old Homes near Yeovil" produced around 1905. Each carried the slogan "Everything St IVEL is Perfect".

From my

collection

The cottage at Ninesprings - this example posted in 1914.

From my

collection

A postcard of Newton House with the River Yeo in the foreground.

From my

collection

Another postcard of Newton House and the River Yeo.

From my

collection

Another postcard in the series, this time of Preston Great Farm colloquially (and incorrectly) known as Abbey Farm.

From my

collection

Another postcard in the series showing Barwick House.

From my

collection

Another postcard of 'Abbey Farm' from the Aplin & Barrett's St Ivel series - but this time it's Abbey Farm in Montacute..

From my

collection

The first of two postcards in the series featuring Brympton House.

From my

collection

.... and the second postcard featuring Brympton House.

From my

collection

.... and one featuring Brympton Farm.

From my

collection

.... and Compton House.

From my

collection

Moving out of Yeovil completely, this postcard features Montacute House.

From my

collection

This final postcard of the series features the Cattistock Hunt and is captioned "Cattistock Fox Hounds. Last hunt of the season 1905-6. Coker Court, nr Yeovil". This postcard was sent in 1907.

the manufacture of meat and fish pastes

The

following is

from an article

from 'Food'

magazine of May

1936 and was

reproduced as a

separate

publication by

Aplin & Barrett.

From my

collection

The firm of Aplin & Barrett Limited was founded in 1897 on the pre-existing partnership of Mr Shorland Aplin and Mr WH Barrett. The headquarters and main factory are still situated at Yeovil in Somerset but continued expansion has necessitated additional factories at London, Westbury (Wilts) and Frome.

The foodstuffs manufactured by this firm embrace the wide range if St Ivel products, well-known examples of which include various types of cheese such as lactic, cream, crustless and Camembert; a large variety of sandwich spreads, for example meat pastes, fish pastes, tongues, briskets, galantines, brawn and sausages; and miscellaneous products among which are cream, butter, honey, lemon curd, Christmas puddings, mincemeat, savouries and soups.

The parent works, at Yeovil, comprise two main buildings occupying about three acres. In one are housed the departments dealing with dairy products; the other is used almost exclusively for meat products. It was this latter building which we visited for the purpose of this article.

This building was erected only three years ago and is consequently arranged and equipped in accordance with modern ideas. It has a frontage of 64 feet and a depth of 240 feet and consists of four floors. Special care has been given to all features contributing to a high standard of hygiene and cleanliness. The entire building is faced internally with white glazed bricks. The rooms are lofty and spacious and all corners are rounded. The floors are concrete and admirably drained. The windows are large and are constructed of prismatic glass to ensure even lighting.

The whole building is under air pressure, the air being drawn in at the roof, filtered, and forced into the building along one side at a height a little above the level of each floor. On the opposite side of each floor it is extracted at ceiling level, and in this manner the air is exchanged every fifteen minutes. Each floor is equipped with basins and sinks for cleaning utensils and for use of the employees. Equipment which comes into contact with food is sterilised by steam. On each floor a passage running the length of the building is fitted with the Morris conveyor system.

Preparing and Filling

The raw materials are brought from cold storage to the preparing room. All fish and meats are carefully scrutinised by a staff of highly skilled examiners whose capacity for assessing the quality of these materials is quite uncanny. The ingredients are weighed out and passed twice through Alexander mincers (William Douglas & Sons Ltd) and then through Premier mills.

From my

collection.

This

photograph

features in my

book "Lost Yeovil"

The preparing room, where raw materials are weighed out, passed twice through mincing machines and through a battery of Premier mills (on the left).

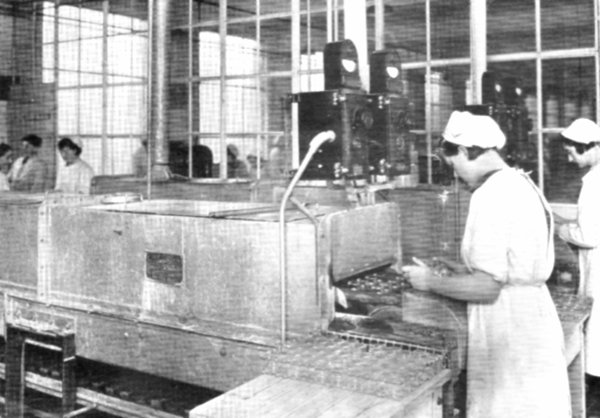

The paste passes to the filling room where it is charged into Jackson fillers (the recent and improved models of this filler are now made by Jackson Crockett & Co Ltd) from which the glasses are filled by a girl at one end of a stainless steel table equipped with a travelling belt. Succeeding girls level off the paste, wipe the rim of the glasses, insert the parchment circles, place on the rings and caps, seam on the caps by aid of a Wallis capper, and finally deposit the pots in wire baskets together with metal labels giving the batch numbers.

From my

collection.

This

photograph

features in my

book "Lost Yeovil"

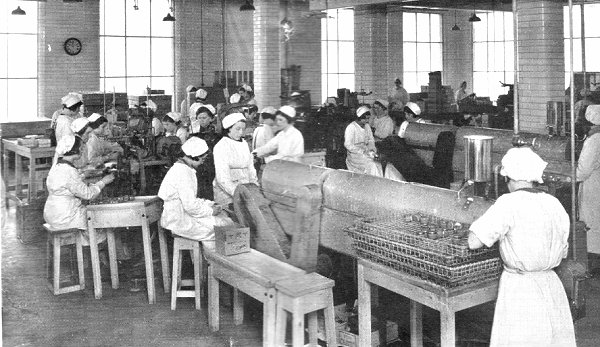

The filling room. Girls are seen filling the paste into glasses, preparing the tops in several stages, and seaming the caps. Finally, the pots pass to the girls on the right, who place them in wire baskets.

It is interesting to note the care taken to ensure cleanliness of the glass containers. They are unpacked in an out-house so as to keep and foreign matter out of the factory. The pots are brought into the washing room in wire baskets, each pot being placed in an inverted position. They are then passed through a Worssam washing machine and on emerging are again placed mouth downwards in wire baskets ready for passing to the paste filling machines.

From my

collection

This photograph shows the two machines for cleaning the glasses, seen emerging clean and dry to be placed upside down in wire baskets.

Retort and Labelling Rooms

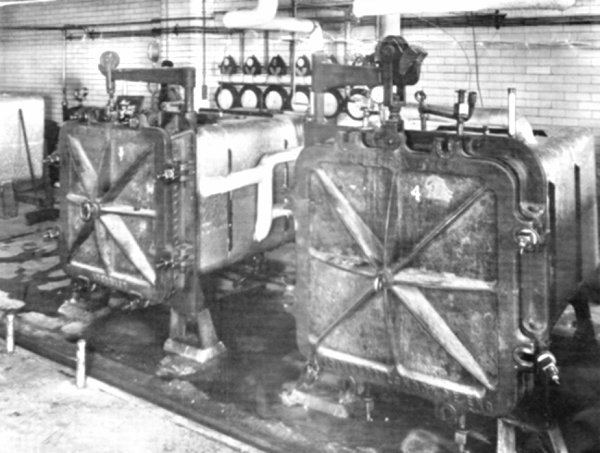

The baskets of pots are conveyed to the retort room by means of a Morris runway. In many factories the condition of the retort room is a little disappointing. Not always is proper attention given to the removal of steam from the premises. In this instance a duct for extraction of the steam had been placed above the retorts and a Sirocco fan discharges the steam into the outer air. The concrete floor is in good condition and free from excessive moisture. A battery of horizontal Milne and Waller retorts has been installed and fitted with instruments (Cambridge) for full thermostatic control. From each retort samples are taken from six different points and sent to the laboratory for bacterial examination.

From my

collection

This view is the retort room. Two horizontal retorts are shown with thermostatic control instruments behind.

After sterilisation the pots are taken from the retort room and sent to the labelling room where they are passed through a Worssam washer, then dried and polished. After this they are labelled (Purdy machines) and the labels subsequently wiped to remove any surplus gum. A batch number is put on each pot.

The pots are now packed into corrugated boxes, each holding two dozen, together with a display carton. The boxes are taped, and both variety and batch labels are affixed on the outside. The boxes are stacked on boards and taken by lifting trucks down the lift to the stock room.

From my

collection

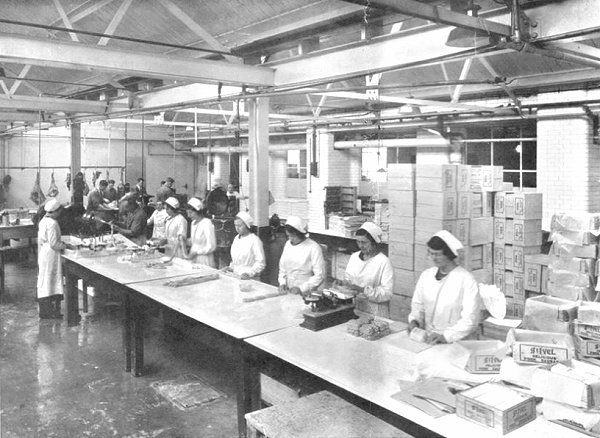

Labelling Room. Pots of paste passed through washers (right) and labelled (left), after drying and polishing (see an example of a paste pot above).

Stock Room

Here they must remain for three or four days until they are passed by the laboratory as sterile, after which they are ready for dispatch.

The Laboratory

An important part of the routine work of the laboratory is to apply bacterial tests to all processed goods before they are allowed to leave the factory. The other part of its routine work is to subject all incoming raw materials to chemical examination. In addition to this, the laboratory is constantly engaged upon research work aimed at effecting any possible improvements in the processes and also the products. Other duties comprise the control of temperatures and times of retorting operations and the checking of the sterility and general cleanliness of the plant and equipment used throughout the factory.

Butcher's Room

Here the meat is prepared for the sausage, pie and small goods departments. The meat is boned in the usual manner, and then passed through the Silent cutter.

Pie Room

The flour, lard, salt and other ingredients used for preparation of the pie pastry are weighed into a Baker Perkins dough mixer. The dough for the shell of the pie goes through a Baker Perkins divider and thence to a Jackson pie moulding machine adjustable to any required size. The dough for the lids is run through a Baker Perkins pastry brake and thence to a Jackson lidding machine.

Weighed amounts of the meat and eggs are then filled into the pie shells, the lids placed on and painted with egg yolk.

Baking is done in a Baker Perkins bank of coke fired ovens. On emergence, the pies are tipped out of the tins and placed on wire trays which are conveyed through a cooling tunnel. On reaching the delivery end, after a period of about twenty minutes, additional jelly is injected into the pies to make up for losses during boiling.

The pies are then placed in a series of cooling lockers where they remain until they have become quite cold at their centres. Finally the pies are packed into individual window cartons, which then go into wooden outers for dispatch.

From my

collection.

This

photograph

features in my

book "Lost Yeovil"

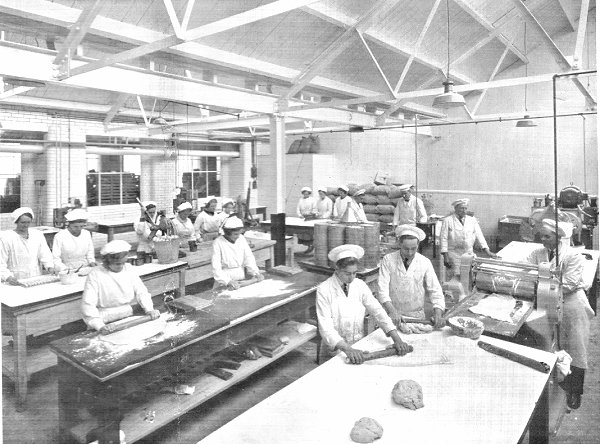

The pie room, with the dough mixer and pastry-brake on right.

The Sausage Room

The meat received from the butcher's room is passed first through a Silent cutter, then through an Alexander mincer and finally through a Baker Perkins mixer. The sausage meat is filled into casings in the usual way, then wiped, weighed and boxed.

From my

collection.

This

photograph

features in my

book "Lost Yeovil"

The sausage room, showing filling operations (left), followed by linking, weighing and boxing.

In conclusion we wish to thank the directors of Aplin and Barrett Ltd for permission to visit their works and obtain the information for this article.