Tenth Exhibition 2024-25

The Tenth Exhibition - presented by Yeovil's Virtual Museum

Leather Gloving in Yeovil

The leather and gloving industries of Yeovil

Taking several months to assemble, this is the largest exhibition presented by Yeovil's Virtual Museum to date. Because the leather glove industry was so inextricably linked to Yeovil for centuries, it was considered important to delve into the history of Yeovil gloves in greater depth than the normal exhibitions.

Nevertheless, Yeovil's Virtual Museum contains a vast amount of information on the gloving and associated industries in the town and this exhibition can only ever be a précis. For all aspects of leather and gloving in Yeovil presented in much greater depth than this exhibition, click here.

-

Gloving Glossary (use your browser's back arrow to return here)

-

Leather Glossary (use your browser's back arrow to return here)

![]()

A History of Gloving in Yeovil

That gloving as a trade has been carried out in Yeovil for centuries, was borne out in 1349 when the Bishop of Bath and Wells was assaulted by a crowd that included six Yeovil men; Thomas Skynnare, Nicolas Skynnare, Adam Tannere, Robert Bras, tanner, Hugh le Glovere and Philip Glovere - effectively men from three different related trades; skinners, tanners and glovers. The Bishop's Register described the Yeovil men as "sons of perdition forming the community of the said town."

The 1784 British Directory listed five glove manufacturers in Yeovil and in 1794 listed six "glovers, lamb and kid dressers". In the 1797 edition it reported of Yeovil "an extensive glove manufactory flourishes here which is considerably revived in recent years on account of the principal manufacturers importing and dressing their own kid and lamb skins." This is a veiled reference that the industry had been suffering due to the illegal importation of French-manufactured gloves. The British government had, from time to time, attempted to ban the import of French gloves by statute with ever-growing success and a consequential growth in Yeovil's fortunes.

Collinson, writing in 1791, stated "There was formerly a large manufacture of woollen-cloth; but now the principal one is of leather-gloves, in which a great number of hands are constantly employed." and "a great many women constantly employed in glove-making". In 1822 C & J Greenwood, writing in 'Somersetshire Delineated' noted that "The woollen trade formerly flourished here, but the principal manufacture at present is that of gloves, which employs a great proportion of the population."

In 1826, however, the legislation banning the entry of foreign-made gloves was repealed with a consequential catastrophic effect on Yeovil's gloving industries. On 21 May 1829, the Sherborne & Taunton Journal reported the following "The situation of our neighbouring poor who used to find employment in the glove manufactory in the town of Yeovil and all the adjoining districts, is, we regret to say, very distressing; and when we look at the extent of the importation of foreign gloves, we see little prospect of any improvement. The quantity imported this year to the end of the month of April is 24,813 dozen, which would have given employment for 100 days to 1,000 women and children for the sewing, and a proportionate number of men and boys in the dressing and preparing the leather."

The following is from "The History of the Glove Trade" written by William Hull, a Yeovil glove manufacturer, in 1834.

"The town of Yeovil, formerly much celebrated for its manufactures of dowlas, ticks, &c, has for nearly three centuries been so for the manufacture of gloves of the finer kinds, as well as military gloves. The latter is now in a state of decay, partly owing to improvident alterations in the military supply. These gloves are made from native skins. Imitation "Limerick" and "York tan gloves" were formerly made in Yeovil, but of late years very few. At present the manufacturers are employed in making men's and women's fine gloves, which pass in the retail shops under the denomination of kid gloves, but are, in reality, made from lamb-skins, imported from Italy, Spain, and Germany. These skins are mostly dressed into leather in Yeovil, in which place the manufacturers are leather-dressers, and large dealers in wool, as well as glovers. The great importation of French gloves annually, is a complete check to the prosperity of the trade of this place; because, the moment that the glovers, by reducing the quantity produced, endeavour to gain a remunerating price, the wholesale dealers in London give increased orders to the French manufacturer, and thus neutralise the efforts of the native manufacturer. The making of gloves from foreign skins has, for several years (owing to the unnatural competition with France), been so unprofitable as to occasion repeated applications to Parliament for protection - hitherto without success.

The non-remuneration of the Lamb Glove Trade in Yeovil has occasioned many of the manufacturers there, to become makers of kid gloves, in imitation of London-made gloves. The quantity of gloves made in Yeovil, of all sorts, may be estimated at 300,000 dozens annually; and the number of men, women and children employed in the place, and the adjoining districts (spreading over twenty miles), amounts, perhaps, to 20,000. The operation of the 'free-trade system' on the town of Yeovil will be well illustrated by the necessity of maintaining one or two troops of dragoons continually in the town and neighbourhood, where, a few years ago, a horse-soldier would have been looked upon as a sort of Centaur by the lower orders of the people." This, apparently, was a direct result of the furore caused by the 'Tolpuddle Martyrs' that had an alarming effect on Yeovil's glove manufacturers who feared the worst in these depressed times.

In fact, in 1834, the first trade union in Yeovil was created with some 200 glovers enrolled. But, in what amounted to a knee-jerk reaction by the leading manufacturers, with the assistance of local magistrates, the trade union was very quickly quashed. However Hull later added, as a footnote, "The dragoons have been lately withdrawn - the demand for gloves has increased" and, indeed, Yeovil's fortunes gradually changed for the better.

By 1840 there were 36 Yeovil glove manufacturers listed in trade directories as opposed to the six of 1794. As the leather and gloving industries grew, so too did the population of Yeovil. In the 1820s the population stood at around 5,600 but by the 1890s had grown exponentially to around 13,500. It has been estimated that between 70% and 80% of the town's population were involved in the leather, gloving and associated industries.

Vickery wrote in 1856 "There are made upon the average in Yeovil, about 4,600 dozen pairs of gloves weekly, and in the neighbourhood about 3,500 dozen pairs; employing upwards of 10,000 persons. The wages paid yearly by the Yeovil manufacturers average in amount about £80,000 (around £75 million at today's value); and by those in the neighbourhood, from £31,000 to £34,000."

The leather and gloving industries of Yeovil slowly increased throughout the latter half of the nineteenth century. There was a short hiatus at the outbreak of war in 1914 due to a lack of materials and a shortage of labour and at this time the industry came under Government control. Following the war there was a brief boom in the industry nationwide but this was not to last long and a long and gradual depression set in. The government lifted the restriction on the importation of German-manufactured leather gloves and at the same time America imposed a tariff on imports to protect its own manufacturing. In Yeovil the industries were further hit by the expansion of engineering and aircraft production in the town, both of which could offer far greater remuneration to their workers than could the leather and gloving industries.

Despite an inter-war boom in the gloving industry, with the number of glove manufacturers increasing significantly as shown in the chart below, after the Second World War the decline of the gloving industry hastened even further. In April 1989, the last of Yeovil's glove manufacturing companies, Freke & Gifford Ltd of Pen Mill Trading Estate, closed blaming cheap foreign imports, thereby ending a centuries-old craft industry in the town. September 2023, saw the closure of Pittard's, the last major leather company in Yeovil.

![]()

Leather Glove Making Processes

The following is précied from a publication called "Where to Buy - Yeovil", published in 1890.

From skin to glove, the process consists of two separate departments - the dressing yard where the raw hides are dressed before going to the glove maker in the glove factory proper, in which the prepared leather is finally turned into finished goods.

The hides, principally lamb and kids skins are taken in their raw states and with the wool on, to the skin room preparatory to being transferred to another large room, on the floor of which they are spread out to dry. The wool is then separated from the hide by chemical process, and has no further use in the factory, it is sold as it is.

The hides are next scraped and placed in large tumblers containing alum and salt, with which are mixed immense quantities of the yoke of eggs. From these tumblers the skins go to the vats, to be drenched with the preparation technically known as 'pure' (primarily dog faeces), and are steeped in a mixture of meal and water, which gives them softness, pliability and face. After this they are dried, either in the open air or in large steam-heated drying rooms. They are next beaten in stocks to soften them, and are laid by in a store-room for about three months. When they have remained here long enough they are sorted into different species and qualities. This finishes the preparatory process.

Having entered the glove factory proper, the skins are washed in a bath of alum and salt, and then dried either in the open air or in artificially-heated rooms. They are next bathed in yoke of eggs, sorted and taken to the dying rooms, where the various shades of colour are imparted to them using dyes of various colours. After being again dried they are once more slaked to stretch them, and shaved or planed to render them of uniform thickness. This finishes the preparation, and they are now ready for being 'tranked', or cut into shapes by machinery (see below) - a process originally performed manually.

![]()

The following collection of colourised photographs show the various departments of Clothier, Giles & Co in the 1930s.

A leather dresser, or currier, applies a variety of techniques to tanned leather to make it strong, flexible, and waterproof. These techniques include:

-

Dressing: Involves shaving, dyeing, re-tanning, setting, drying, and trimming

-

Stretching and burnishing: Produces a uniform thickness and suppleness

-

Dyeing and chemical finishes: Gives the leather its desired color

After currying, the leather is ready to be used in glove making.

General view of the leather dressing yard and glove factory.

The pit house.

The dressing yard.

The staining shop.

The wheeling shop.

The ironing shop.

The cutting shop.

The trimming department.

The webbing and counting room.

The machine room.

The banding and boxing department.

![]()

... and a little later

The cutting room of Clothier & Giles glove factory, photographed in the early 1960s.

![]()

Gloving Equipment

The Gloving Donkey

Winter's invention consisted of a clamp mounted on a wooden pedestal. The clamp was spring-mounted and operated by a foot pedal. Along the edge of both sides of the clamp were strips of brass with evenly spaced teeth which held in the glove firmly but enabled the glove sewer to produce accurate stitching by using the brass teeth as a guide for the needle.

At this time, of course, all gloves was stitched by hand and the even and accurate stitching the device enabled was an important step in glove manufacturing.

During the nineteenth century all the glove manufacturers employed outworkers, invariably women and girls who worked at home sewing gloves. The gloving donkey enabled more accurate and speedy glove production, even enabling girls as young as eight years of age to produce work of an acceptable standard. The gloving donkey was in constant use until the gradual introduction of the sewing machine in the 1880s.

The head of a gloving donkey either made by, or sold by, Henry Little - gunsmith and ironmonger of Silver Street. Note the fine teeth which enabled the production of fine, even stitching even by the inexperienced.

This

photograph

features in

my book "A-Z

of Yeovil"

James Winters' invention, the gloving donkey, seen in use in this photograph enabled the accurate stitching of gloves and ensured a higher quality of finished product.

The Gloving Die Cutter, or 'Web'

Die-cutting is a process whereby a die is used to cut through materials, such as leather, on a die press. The process allows for making an identical cut into the leather numerous times. Die-cutting in Yeovil was chiefly a 20th-centry innovation in the gloving industry. The following description of the gloving web, is courtesy of David Shore which he used in the 1950s.

"The web, was constructed on a 1/4" thick steel back-plate. There was a wood spacer topped with a No 14 gauge thick face plate. The cutters were made from 'high carbon knife steel' forged into shape in a blacksmith's forge and shaped using zinc templates. They were then heated red hot in the forge and quenched in whale oil. The hardened blades were then slowly reheated until the whale oil on the blade caught alight in the flame - this indicated the temperature for tempering was reached and then the blade was finally quenched.

A die

cutter, or

Web, used to

stamp

leather

glove

blanks.

Once all the knives were assembled in the 'Web', the cutting face of the knives were levelled on a large sanding disk. The whole assembly was then dismantled and each knife was brought up to edge on grinding wheels running up and away from you. The grinding wheels were made from wood with a strip of leather stuck around it with animal glue and little oak pegs. The leather was then painted with more hot animal glue and rolled in Emery grit. The grinder was quite noisy so we learnt to lip read. I remember the leather once coming unstuck and a knife blade was flung through Mr Hallett's overhead office wall.

Once the blades were brought up to edge they were finally honed with oiled Arkansas stone. There was also a Bolton opening for the thumb which was adjustable. The back plate was radiused all round and then draw filed and polished and buffed to look like chrome and the face plate was screwed to the back plate with 3BA countersunk screws and their heads were polished and buffed to look like chrome. We also made Thumb punches that were formed from the same knife steel."

Heated Glove

Hand

|

Above, is a brass heated glove hand, dating to around 1950, manufactured by WH Hallett & Son of the Halson Works, Sherborne Road, and seen below attached to the heating element. |

An industrial glove heater, 55cm high, with a brass heated hand (as previous photograph), made by WH Hallett & Sons and probably dating to the 1950s. The main dial is by Ashley Brothers of Yeovil. The inset is a close-up view of the hand base.

The Glove Sewing Machine

After many generations of Yeovil women and girls sewing gloves by hand, mechanisation came to the Yeovil gloving industry in the twentieth century. This is a 'Success' glove sewing machine, made by Allbrook & Hashfield of London around 1930 and retailed by Hyde and Wakely of Yeovil. This example came from the Yeovil Glove Company of the Nautilus Works, Reckleford.

... and finally

Glove Finger Stretchers

Spring-loaded wooden finger-stretchers for leather gloves from Hannam & Gillett of Yeovil, ironmongers of the Borough and therefore dating to the period from 1843 to 1870.

This pair of glove stretchers might have belonged to either a man or a woman. They were used to help ease tight kid gloves so that they would fit over the fingers. They also helped restore the fingers of the gloves after washing, which made them wrinkled and stiff. The user would place the pointed end of the glove stretcher into the finger of a glove and then compress the handle together so that the two ends splayed out, hence stretching the kid leather. During the 19th century the essential mark of a lady was to have small hands and feet and it was partly for this reason that close-fitting gloves were worn. A well-fitting glove was also an important complement to the tailored appearance of men's clothing. Glove stretchers therefore became a vital wardrobe accessory as they assisted the wearer in easing their gloves.

From my collection

|

|

Somewhat later than the glove stretchers above, this pair of wooden glove stretchers, date to around 1915, and were manufactured by WH Hallett & Son of Yeovil. At left is a detail view of the inscription. "Everything for the Glover". |

![]()

Victorian (1856) Leather & Gloving Wages

In his book of 1856 entitled "A Sketch of the Town of Yeovil" Daniel Vickery listed the average weekly wages of various trades (assuming fully employed) in the leather and gloving industries, which are tabulated below.

The nineteenth century gloving and leather trades occupied whole families – a man might be a glove cutter or leather dresser while his sons were apprenticed, frequently in the same trade as their father. Boys, from about the age of 9 or 10 were frequently employed in the factories until the age of 14 when they would enter an apprenticeship. The man's wife and daughters usually sewed gloves working from home, many wives working part time, in what was essentially a cottage industry. Girls sewed from about the age of 7 and were often employed before that to 'tie off the threads' left by the sewers. Materials were supplied to the women and girls by a 'bagwoman', on behalf of the glove manufacturer, who later paid them by the completed dozen pairs of gloves.

Finally, Vickery observed "Female servants' wages are high in proportion to towns of a similar standing, and perhaps there is no town in England of its size, where so many persons of either sex and of all ages who need employment, may, if they wish, find it."

The table below highlights the 'hierarchy' of trades which is not readily discernible from other sources, such as census returns. Today's value is based on the 'Historic Standard of Living' calculation which measures the purchasing power of an income or wealth in its relative ability to purchase a (fixed over time) bundle of goods and services such as food, shelter, clothing, etc., that an average household would buy.

For comparison the average weekly earnings of agricultural labourers is included. The farm labourers also usually had a daily allowance of cider, especially at harvest times when it might be a gallon each day.

|

Trade |

Average Earnings |

Today's value |

| Glove Cutter | 21/- to 30/- per week | £85.62 to £122.31 |

| Leather Dresser | 21/- to 24/- per week | £85.62 to £97.85 |

| Leather Dyer | 20/- to 25/- per week | £81.54 to £101.93 |

| Leather Parer | 18/- to 21/- per week | £73.39 to £85.62 |

| Apprentices | 15/- to 20/- per week | £61.16 to £81.54 |

| Women workers | 4/- to 6/- per week | £16.31 to £24.46 |

| Boys, aged 10 to 14 | 1/- to 2/6d per week | £4.08 to £10.19 |

| Girl workers under 14 | 1/- to 2/6d per week | £4.08 to £10.19 |

| For comparison | ||

| Agricultural Labourers | 7/- to 10/- per week plus cider | £28.54 to £40.77 |

![]()

Glove Manufacturers - Leaders of Yeovil Society

By the 1830s, the increasing population of the town had led to such overcrowding and very poor living conditions for the majority of the poor, that steps were deemed necessary to improve the town's condition. This ultimately led to the creation of the Improvement and Town Commissioners in an attempt to improve the general conditions in the town which, at this time, were all but medieval with narrow streets, open sewers, and so forth. It is no coincidence that the majority of the newly elected Town Commissioners were, in fact, leading glove manufacturers. While their stance on trade unions was, perhaps, questionable, there could be no doubting of their earnest intentions towards the betterment of general conditions in Yeovil.

Clicking on

the name below,

will take you to

that person's

page in Yeovil's

Virtual Museum.

Use your

browser's 'back'

button to return

here.

- Bide, William Snr - Alderman, Mayor of Yeovil 1856-58, Magistrate

-

Bide, William Jnr - Improvement Commissioner, Special Commissioner, Magistrate

-

Clothier, Sidney - Alderman, four times Mayor of Yeovil, 1927-29 and 1935-37.

-

Dampier, Thomas - Town Commissioner

-

Gawler, George Wrentmore - Mayor of Yeovil, 1892

-

Gould, George Henry - Alderman, Mayor of Yeovil, 1917-18

-

Greenham, Charles - Custos of Woborn Almshouse, Town commissioner

-

Greenham, Frederick - Burgess, Improvement Commissioner, Mayor of Yeovil 1855-56

-

Greenham, John - Burgess, Improvement Commissioner

-

Johnson, William Walter - twice Mayor of Yeovil 1902-04

-

Mayo, John Ryall - Improvement and Town Commissioner, Yeovil's first Mayor 1854

-

Penny, Henry - Churchwarden, Vestry member, Town Commissioner

-

Phelps, Henry Bryant - Town Commissioner, Special Commissioner, Magistrate

-

Pittard, Charles - founder of the leather business

-

Raymond, Edward - twice Mayor of Yeovil 1864-67 and 1879-80, Magistrate

-

Raymond, John Greenwell - Magistrate

-

Raymond, William - Magistrate

-

Southcombe, Herbert - Mayor of Yeovil 1889-90, Magistrate

-

Tucker, Robert Jnr - Town Commissioner, Mayor of Yeovil 1858-60, Magistrate

-

Whitby, Elias Jnr - Town Commissioner, Mayor of Yeovil 1862-64, Magistrate

-

Whitby, Elias Lyndall - Mayor of Yeovil 1878-79, Magistrate

![]()

Some Leather Glove Manufacturing Companies

Below are

précised

histories of

several

glove

companies.

Again,

clicking on the

name will lead

top that

company's page

in Yeovil's

Virtual Museum.

Use your

browser's 'back'

button to return

here.

![]()

|

Arnold

Glove Co

Ltd (Addlewell Lane) The company was listed as glove manufacturers in Addlewell Lane in Kelly's Directory of 1923, although it was not officially floated as a new company until 1925. The directors of the company were glove manufacturers Arthur Stanley Arnold and William Parker (who was also the Company Secretary), together with tobacconist and hairdresser Joseph Arnold. The company was listed in Kelly's Directory of 1935, Edwin Snell's Directory of 1954 and Foord's Directory of 1964. |

|

|

|

Atherton

&

Clothier

Ltd (Court Ash) George Atherton (1817-1910) was advertised as a glove manufacturer of Court Ash in the 1866 edition of the Post Office Directory. After George's retirement, his son Henry took over the glove manufacturing business and renamed it Atherton & Co. It was listed as such in Whitby's Yeovil Almanack Advertiser of 1903 and in Collins Yeovil Directory of 1907. By 1919, after a probable merger with the glove manufacturer Sidney Clothier, the company had become Atherton & Clothier Ltd, glove manufacturers of Court Ash, and were listed in Kelly's Directories of 1919 and 1935. Also in 1935 they opened a dressing yard in Addlewell Lane. By 1964 the company had moved to the Addlewell Lane premises and was listed in Foord's Directory of 1964 and Kelly's Directories of 1968 and 1970. The company closed in the 1970s.

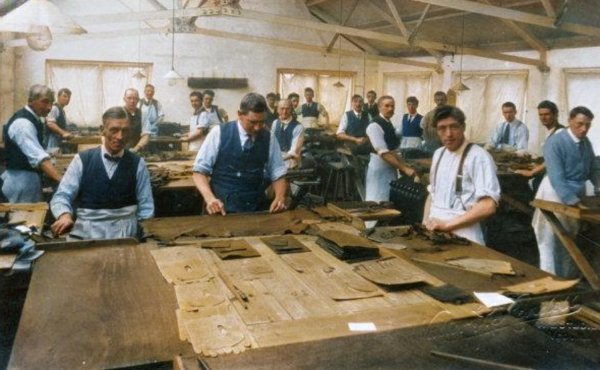

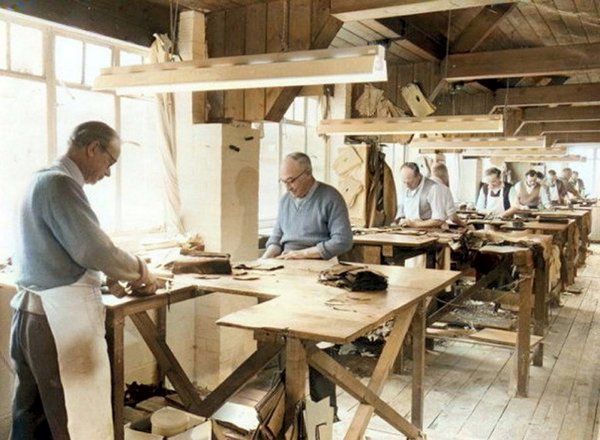

Atherton

& Clothier's

table glove

cutting shop

in a

colourised

photograph

of the

1920s. |

|

|

|

John

Barber

This photograph was taken in the 1960s and looks west along Preston Road and the road running off to the right is newly-constructed Willow Road. The three-bay house end-on to Preston Road with a corner shop in its left-hand side is Providence Cottage. John Barber lived in Providence Cottage with his family certainly from 1861 until his death in 1894. The building at right was originally John's glove factory and leather tannery but converted into a flour mill known as Newis' Mills after his death. Both cottage and mills were demolished shortly after this photograph was taken. |

|

|

|

WH Bicknell Ltd (Middle Street ) WH Bicknell Ltd were a 20th century company of leather merchants. They were based in Middle Street and were listed in the 1935 edition of Kelly's Directory. By the time of Kelly's Directory of 1970 the company were at the Allingham Works, St Michael's Avenue. In 1972 the company were recorded as having 46 staff but closed shortly thereafter. Bicknell Gardens now stands on the site. |

|

|

|

Blake & Fox (Summerhouse Terrace) Blake & Fox were leather dressers and glove manufacturers throughout the first half of the twentieth century with a large factory and dressing yard in Summerhouse Terrace. They were listed as glove manufacturers of Mill Lane in Kelly's Directory of 1919 and in Kelly's 1935 edition as glove manufacturers of Summerhouse Terrace. There were two entries in Edwin Snell's Directory of 1954; one as leather dressers and the other as glove manufacturers of Summerhouse Road (sic). Despite this there is hardly any information in the records of the company.

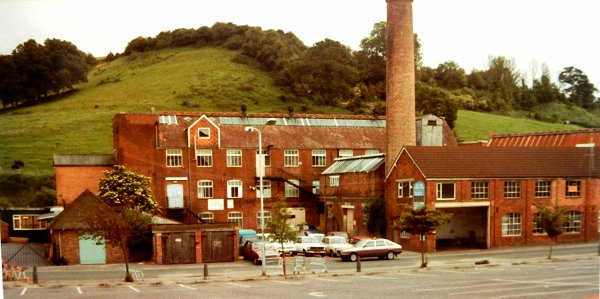

The Blake and Fox factory in Summerhouse Terrace at the foot of Summerhouse Hill, photographed in 1984. |

|

|

|

Boyd & Fooks (South Street) In 1856, Boyd and Fooks were the largest glove manufacturers in Yeovil. In 1858 they employed 1,156 men and 8,050 women. Despite this there is hardly any information in the records of the company. The Fooks of the company was wealthy glove manufacturer Thomas Fooks. Their factory was located on the north side of South Street and to the east of Union Street, in the area now occupied by the car park between Tabernacle Lane and the Penn Hill Pharmacy.

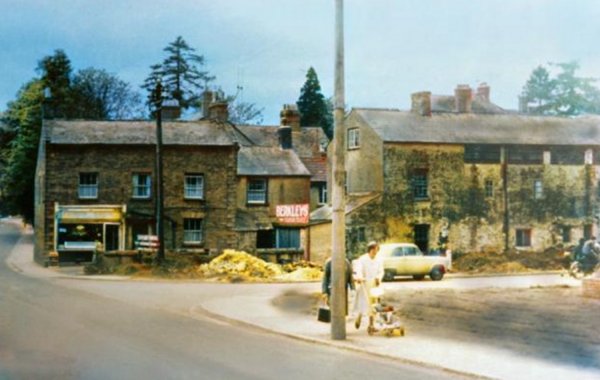

South Street photographed from Penn Hill. The three-storey building at centre was previously the glove factory of Boyd and Fooks, but at the time of this 1960s' photograph was the premises of Hill Sawtell. |

|

|

|

Clothier,

Giles &

Co Ltd (Addlewell Lane) In 1889 George Giles, a leather tanner, and his partner glove manufacturer Frederick Clothier (father of Sidney Clothier, also a glove manufacturer and four-times Mayor of Yeovil), formed a company called Clothier Giles with a factory in Addlewell Lane next to Dodham Brook. Clothier, Giles & Co Ltd closed the gloving side of the business in 1975 to concentrate on the production of leather clothing. The company finally ceased trading in 1986.

The factory seen from Park Street in a colourised photograph of the mid-1960's. |

|

|

|

S & G Cooper Ltd (Highfield Road) S&G Cooper was a small glove manufacturing company of the early to mid-20th century and operated at the Highfield Works in Highfield Road. They are known to have been active in 1935 when they were listed in Kelly's Directory of that year, in which they were listed as glove manufacturers of Highfield Works. They were listed again in Foord's Directory of 1964.

The Highfield Works photographed around 2005. By this time is was a small trading estate, but was demolished shortly thereafter. The site is now waste ground. |

|

|

|

Freke & Gifford (Highfield Road) In April 1989 the last remaining glove factory in Yeovil, Freke & Gifford Ltd of Pen Mill trading estate, closed blaming mild winters and cheap foreign imports on falling sales. This ended a centuries-old craft industry that had been the mainstay of Yeovil which, at its peak, employed thousands of people, estimated at around 70% of the town's population in some forty different glove factories as well of tens of thousands of outworkers in Yeovil and its outlying villages. The company of Freke & Gifford Ltd was established in a bicycle shed in Preston Road in 1928 by William Freke and his partner Jack Gifford and they employed Freke's wife to do the sewing. The company moved into new premises in Highfield Road, on the corner with Eastland Road, in 1934. This was the first purpose-made glove factory to be constructed in steel and concrete, as opposed to the traditional Yeovil red brick. At its peak, during the Second World War when there was a huge demand for motorcycle gauntlets for the armed services, the company employed some 50 full-time staff and 200 out-workers. The company was listed as glove manufacturers of Highfield Road in Edwin Snell's Directory of 1954, Foord's Directory of 1964 and Kelly's Directory from 1968 through to 1974. In 1989, as glove manufacturers of Pen Mill trading estate, they featured in the Western Gazette as the last Yeovil leather glove factory to close. The site was cleared and Highland Court built in the 1990s (I think).

The Freke & Gifford glove factory on Gordon Road and Eastland Road. Photographed in the 1980s. |

|

|

|

Hawkins, Jesty & Ricketts

(Middle Street ) Hawkins, Jesty & Ricketts was a glove manufacturing company during the first half of the twentieth century. The partners were John William Hawkins, John Albert Jesty and William Ricketts. Their glove factory in Higher Kingston had earlier belonged to glove manufacturer Henry Bryant Phelps and later by his brother's company, Robert Phelps & Co. They also had a dressing yard at Dodham. Hawkins, Jesty & Ricketts first appear in the trade directories as Glove Manufacturers of Higher Kingston in the 1903 edition of Whitby's Yeovil Almanack Advertiser. They were listed simply as Hawkins & Jesty in the 1907 edition of Collins' Yeovil Directory but returned to Hawkins, Jesty & Ricketts, Glove Manufacturers of Higher Kingston in Kelly's Directory of 1919, in which they also had a separate listing for their dressing yard at Dodham. The final listing of Hawkins, Jesty & Ricketts appeared in Kelly's Directory of 1935 as Hawkins, Jesty & Ricketts Ltd, Glove Manufacturers of Higher Kingston. The leather dressing yard had been demolished by 1946 and the glove factory was demolished in the 1960s as part of the District Hospital redevelopment scheme.

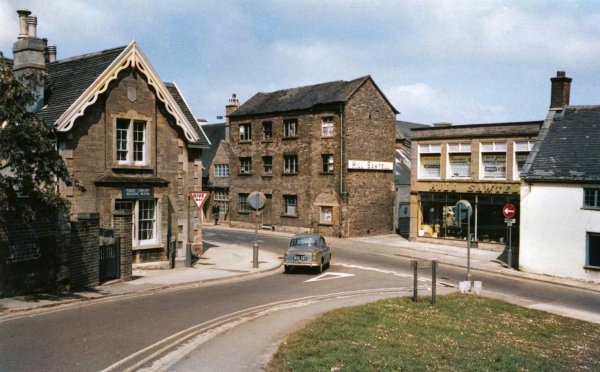

This colourised photograph of about 1965 shows Hawkins, Jesty & Ricketts' glove factory in Higher Kingston, on the north side of the road opposite Kingston Manor House. |

|

|

|

Ivelnap Ltd (Victoria Road) Ivelnap Ltd are known to have been active in 1924, and their letterhead noted 'Established 1889', but were not listed in any of Yeovil's trade directories until 1935 when they were listed as glove manufacturers of Victoria Road in Kelly's Directory of 1935. Around 1936, after the Primitive Methodist Chapel in South Street ceased to be used for worship, the Ivelnap Glove Company down-sized and moved there from their premises in Victoria Road. The company was listed as Ivelnap Gloves (1936) Ltd of South Street in Edwin Snell's Yeovil Directory of 1954. |

|

|

|

Maddley,

Stuart Ltd (Eastville) Stuart Maddley Ltd were a short-lived glove manufacturing company of Eastville, occupying the former glove factory of W Tavener & Son. They were listed in Kelly's Directories between 1968 and 1974. In 1972 they were recorded as employing 31 staff. Their large, three-storey glove factory still stands in Eastville and is photographed below. |

|

|

|

LH Nichols Ltd (Hendford / Brunswick Street) Moving to Yeovil in 1952 Lionel Nichols, together with his brother Alan, established a company of leather dressers and glove manufacturers that was to grow into a small associated group of companies; LH Nichols Ltd, Jones & Turner Ltd and Stirling Leather Ltd. The original main production premises (see photo below) were off Hendford / Brunswick Street, close to the present police station roundabout, and part of the original buildings are now Coopers Mill but production moved firstly to Milborne Port then returned to Yeovil, setting up in the Nautilus Works (see below) around 1990. The company LH Nichols Ltd was described as specialists in 'Slink Lambskins' which it initially imported from South America and later from New Zealand. After a few years the opportunity arose for Nichols Ltd to purchase the New Zealand company that was supplying the raw skins; this became Nichols (New Zealand) Ltd. In 2013, with the end of the lease on the Yeovil factory and the retirement of key staff, production transferred to New Zealand trading as Nichols (New Zealand) Ltd.

The Nichols' tannery seen from Dodham Brook, probably in the early 1960s. |

|

|

|

Parker, Brooks & Long (Addlewell Lane) Parker, Brooks & Long were glove manufacturers and leather dressers of Addlewell Lane. It is believed that the company was originally called Patten, Parker & Brooks in the 1920s. They were listed in Kelly's Directory as early as 1935 as Parker, Brooks & Long, Glove Manufacturers of the Coronation Works in what had formerly been lower class residential properties off Addlewell Lane called Coronation Buildings - the gardens of which had been converted into a leather dressing yard and the houses themselves had been converted to industrial use - the leather and gloving workshops of Parker, Brooks & Long. By 1954 Parker, Brooks & Long had become a limited company and were listed twice in Edwin Snell's Directory of 1954; once as leather dressers and then as glove manufacturers. In both instances as 'Parker, Brooks & Long Ltd of Coronation Works'. Their final listing in any trade directory was in Foord's Directory of 1964. By the 1960s, Parker Brooks & Long had premises at the bottom of Mill Lane, where it met with Summerhouse Terrace (see below).

Photographed in the 1960s, Parker Brooks & Long had premises at the bottom of Mill Lane, where it met with Summerhouse Terrace. Mill Lane is running of to the bottom right, the Parker Brooks Long premises are seen in front of the chimney at left. |

|

|

|

Perrin Leather Co Ltd (Eastland Road Dressing Yard) The Perrin Leather Company Limited was a Private Limited Company, established on 29 July 1924. The company was based at the Eastland Road Dressing Yard and Tannery and the company's registered office was at 17 Hendford. The company was in business for some fifty years. A notice of liquidation was placed in the 26 November 1980 edition of the London Gazette. However it was recorded as going into compulsory liquidation on 29 May 1986 and was finally struck off the Companies Register and dissolved on 3 September 1999. |

|

|

|

R&J Pullman Ltd (Stars Lane) pullman-kit The glove manufacturing company of R&J Pullman Ltd had a history going back as far as 1814 at Woodstock when it was founded by Robert William and John Pullman. The company moved to Yeovil in 1945 when they purchased the Stars Lane factory. They later acquired two further factories in Addlewell Lane and Mill Lane. With a reputation for manufacturing high-quality leather gloves and, especially, leather accoutrements for the army, the company was listed at Yeovil in Edwin Snell's Directory of 1954, Foord's Directory of 1964 and Kelly's Directories of 1968 and 1970. The company closed in the 1970s.

Leather military accoutrements, in this case a leather bayonet frog and a leather belt of "Simplex Equipment", made by R&J Pullman. |

|

|

|

WJ & EG Ricketts Ltd (Addlewell Lane) In 1910 Ernest Ricketts established his own glove manufactory in newly-built Manor Road. The building, photographed below, was later to become the premises of the Raymond brothers. In the same year Ernest's older brother William bought a one-acre site in Addlewell Lane and set up his own leather dressing business. Ernest closed down his Manor Road factory in 1925 in order to join his brother William in partnership. The new company was WG & EG Ricketts Ltd. the company also owned a tannery in Stars Lane, although this was destroyed by fire in 1931. WJ & EG Ricketts & Co, Leather Dressers of Addlewell Lane were listed in Kelly's Directory of 1935 but were most often listed as glove manufacturers in a range of other directories up to and including Kelly's Directory of 1974. In 1983 the WJ & EG Ricketts & Co glove factory in Addlewell Lane was demolished and the Central Acre development was built on the site.

The WJ & EG Ricketts & Co factory in Addlewell Lane. Photographed in 1983, by which time the company had been closed and the factory stood empty. |

|

|

|

WH Slade & Co (Glenville Road) WH Slade & Co was a small glove manufacturing company started by William Henry Slade who was born on 28 August 1892 in New Town. It would appear that WH Slade & Co, glove manufacturers, was started around 1918 as the earliest mention of the company was in 1918 when the they advertised in the Western Gazette. The small factory was, in fact, at the bottom of William's back garden in Glenville Road and the site of the factory is now the car park of Roman Court. WH Slade & Co was listed in Edwin Snell's Directory of 1954 and Foord's Directory of 1964. It was listed in Kelly's Directories of 1968 and 1970, with a final listing in Kelly's edition of 1974.

At left, in the back garden of William Slade, is the glove factory of WH Slade & Co, later the Glenville Glove Company, in Glenville Road. The site is now the Roman Court flats. |

|

|

|

Thring & Luffman (Reckleford) This, the fourth incarnation of the Thring & Luffman company, was first mentioned in Kelly's Directory of 1919 with two listings; "Thring & Luffman, Glove Manufacturers of 64 Reckleford" and the "Thring & Luffman Dressing Yard in Brunswick Street". The double listing was repeated in Kelly's Directory of 1935. In 1954 Thring & Luffman were listed as Glove Manufacturers of Reckleford in Edwin Snell's Directory and the same directory also listed Thring & Luffman Ltd as Leather dressers of Reckleford. The last trade directory entry was in Foord's Directory of 1964 which simply reiterated "Thring & Luffman, Glove Manufacturers of Reckleford".

Chamois skins drying in the air behind Thring & Luffman's Reckleford glove factory, in a colourised photograph of around 1940. |

|

|

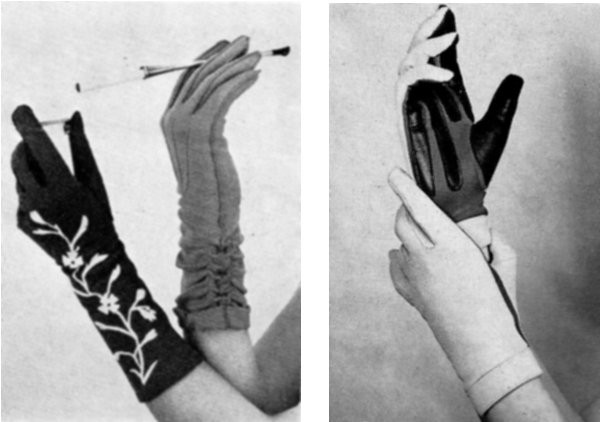

Examples of Yeovil Gloves

Denner and Vaughan gloves in 1964. At left fashion gloves (don't you wish they'd make a fashion come-back?) and at right what was described as "Denner and Vaughan's new feminine washable driving glove with a maximum-grip leather and nylon palm and crimp nylon "waffle" knit back. Colours are black and fashion shades."

Courtesy of

Brian Vaughan

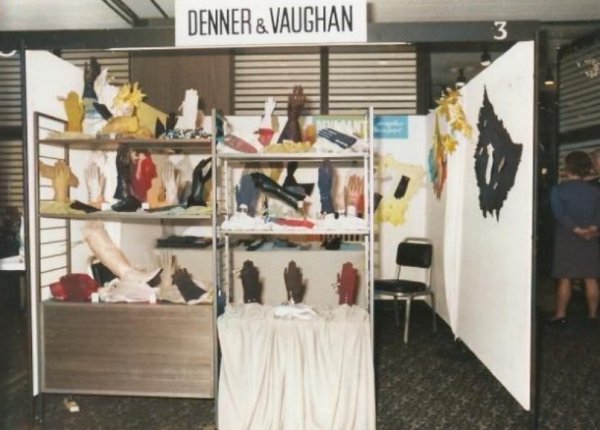

The Denner & Vaughan stand at a trade exhibition in 1968.

A pair of ladies' black suede / calfskin leather gloves made by Freke & Gifford.

Vintage Gould’s soft black kid mid-forearm evening gloves.

A selection of slink lambskin gloves made by LH Nichols Ltd.

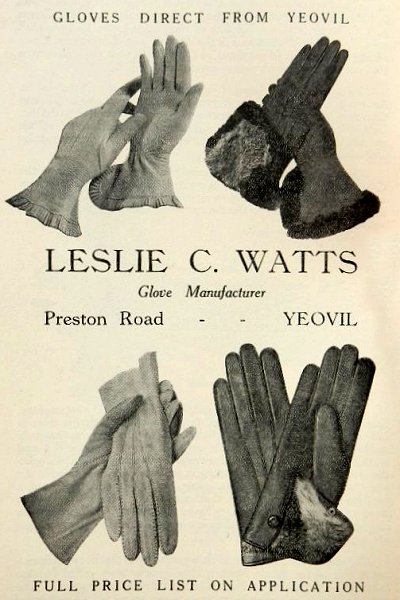

This advertisement appeared in a book from 1931 entitled "In and Around Yeovil and Sherborne". The following year Leslie Watts was made bankrupt blaming, in part, the excessive cost of advertising which did not result in the expected increase in turnover.

Leather ski mittens produced for the army in 1942. White leather mittens with cotton cuff and adjustable elasticated draw string in the wrist with a white cotton webbing strap between the mittens to prevent loss when they are taken off, the strap passes inside through the sleeves of a coat when worn. As worn by ski troops, commandos etc., Dated 1942 Yeovil Glove Company Ltd.

![]()

Surviving Glove Factory Buildings

Many glove factories, leather dressing yards and so forth have disappeared over the years. However, there still remain several former premises now, of course, converted to other uses. Below are shown survivors of Yeovil's gloving heritage.

|

|

||

|

|

Bide's Leather Dressing Yard, Tannery & Warehouse (Eastland Road) Around 1828, William Bide Snr built the large leather dressing factory with a four-storey leather-dressing warehouse on the corner of Kiddles Lane (now Eastland Road) and Reckleford. William died in 1830 and the factory was left to his son, William Bide Jnr, and described in his will as a "newly-built glove factory, a yard and an old loft adjoining and around with a wall and parting door." The building is now derelict. |

|

|

||

|

Brunswick Glove

Co Factory (West Hendford) The Brunswick Glove Co's glove factory in West Hendford is the white building with the car outside. The Brunswick Glove Co was a small glove manufacturing company that started life in premises in Brunswick Street. By the 1950s, the company had moved premises to West Hendford. Their last trade directory listing was in Foord's Directory of 1964. It is now a private house. |

|

|

|

||

|

Court

Ash

Leather

Cutting

Factory (Court Ash) This old building in Court Ash, was originally Atherton & Clothier's leather cutting factory. It became Pandora's 'Discotheque & Bar' in the 1970s. The building survives today as the premises of Yeovil Auctions. |

|

|

|

||

|

Ewens & Robbins

(Alexandra Road) The company of Ewens & Robbins was only listed once in Yeovil's trade directories and this was in 1919, when they were listed as glove manufacturers of Alexandra Road in Kelly's Directory of that year. It is not known which of the Ewens family was connected with this business. Nothing further is known at this time. |

|

|

|

||

|

Foundry

House (Stars Lane) The leather glove factory, now known as Foundry House, was built in Stars Lane in the early 1870s for the glove company of Ewens, Johnson & Co Ltd - a partnership of glove manufacturers Edward Samuel Ewens and William Walter Johnson. It is of red brick with Ham stone and brick dressings under a slate roof and comprises a three-storeyed building of seven bays. |

|

|

|

||

|

Gawler's

Glove

Factory (Wyndham Street) Photographed around 1990, this photograph shows, at centre, the building that had housed Charles Gawler's (later, his son George's) glove factory in Wyndham Street. Charles and his family lived in a house at one side of the factory, while George's grandparents lived in the house on the other side. The building is now three storeys high. |

|

|

|

||

|

Heard &

Co Glove

Factory (Princes Street)

Heard & Co are

known to have

been active in

1930, but were

only listed once

in Yeovil's

trade

directories.

This was in

Kelly's

Directory

of 1935 in which

they were listed

as glove

manufacturers of

7 Princes Street

- believe it or

not, the

three-storey,

red brick

building in this

photograph.

|

|

|

|

||

|

Ivelnap

Glove

Factory (Victoria Road) Ivelnap Ltd are known to have been active in 1924, but were not listed in any of Yeovil's trade directories until 1935 when they were listed as glove manufacturers of Victoria Road in Kelly's Directory of 1935. Their glove factory had earlier, certainly in 1910, been the factory of Clothier, Brooks and Shire Ltd. Around 1936, they moved to what had been the Primitive Methodist Chapel in South Street. |

|

|

|

||

|

Nautilus Works (Reckleford) Denner & Vaughan Ltd were founded in 1950. In 1960 the company moved to the first floor of the administration block of the Nautilus Works, Reckleford, and were listed in Foord's Directory of 1964. The photograph shows Denner and Vaughan staff posing outside the company's works on the first floor of the Nautilus Works in 1964. Denner and Vaughan was wound up in 1976. (See also next). |

|

|

|

||

|

LH Nichols Ltd (off Hendford / Brunswick Street) Moving to Yeovil in 1952, Lionel Nichols established a company of leather dressers and glove manufacturers that became a small associated group of companies; LH Nichols Ltd, Jones & Turner Ltd and Stirling Leather Ltd. The original main production premises were off Hendford / Brunswick Street, close to the present police station roundabout, before setting up in the Nautilus Works (see previous) around 1990. |

|

|

|

||

|

Phillips

& Co (Vincent Street) Phillips & Co were small company of glove manufacturers, run by EA Phillips and WW Leworthy, located in Vincent Street, on the corner with Market Street. The company are known to have been in this building in 1924, but it appears that the company had moved premises by the following year since the building was sold with vacant possession in August 1925. The company went into liquidation in 1975. |

|

|

|

||

|

Leather Dressing Yard

& Warehouse (Lower Middle Street) Hammond & Pickford's leather dressing yard, warehouse, glove factory and office survives today. The property was acquired by Charles Pittard (see next) in 1848 and he remained its sole owner until his death in 1867, after which it passed to his two sons, Charles Wreford and Ebenezer then aged 22 and 19 respectively. |

|

|

|

||

|

Pittard's Tannery & Company HQ (Sherborne Road) To be honest, I really don't know when the Sherborne premises were built - I'm guessing the late 1960s. Pittard's specialised in performance leathers for gloving, footwear and interiors. Pittard's had tanneries in Yeovil and Ethiopia, together with the facility to manufacture finished products in both locations. In September 2023, after a period of 181 years, Pittard's went into administration. |

|

|

|

||

|

Ernest Ricketts' Glove Factory (Manor Road) In 1910, Ernest Ricketts established a small glove factory in newly-built Manor Road. Ernest closed down his Manor Road factory in 1925 in order to join his brother William in partnership. The new company was WJ & EG Ricketts Ltd. The building was later to become the premises of the Raymond brothers who added the shop front. |

|

|

|

||

|

Edwin

Robbins' Glove Factory (Alexandra Road)

Edwin Robbins

Ltd were glove

manufacturers of

Alexandra Road,

being listed in

Kelly's

Directory

as early as

1935. Their

final listing in

a trade

directory was in

Edwin

Snell's

Directory

of 1954. The

small,

two-storey glove

factory still

stands in

Alexandra Road

and is now part

of a small

industrial

estate. The

factory was

later taken over

by glove

manufacturers

|

|||||||

|

||||||||

|

William Tucker's Glove Factory (Reckleford) William Tucker was a glover who ran the Glovers Arms from at least 1871 until his death in 1899. At one time the buildings attached to it were part of a small glove-making factory and certainly two former landlords, James Allen as well as William Tucker, were glovers as well as licensees. The building was later converted to cottages as seen here. |

|

|

|

||

|

Waterloo

House (Waterloo Lane) It is not really known which of the Thring brothers ran the Thring Brothers company of glove manufacturers based in Waterloo Lane. The earliest mention of the company was in Whitby's Yeovil Almanack Advertiser of 1903 which simply listed "Thring Brothers, Glove Manufacturers of Waterloo Lane". The last listing was in Edwin Snell's Directory oof 1954. |

|

|

|

||

|

Young

& Co Glove Factory (Seaton Road) Young & Co were glove manufacturers and in 1931 were listed in Kelly's Directory as being located in Brunswick Street. At some time they re-located to this purpose-built, three storey factory set within residential properties in Seaton Road. The factory, originally built as an engineering works, was built in 1910 and is now flats called Glovers Court. |

|

|

|

||

I hope you enjoyed this exhibition. Tell your chums.